Are you looking for the best CNC plasma table to maximize productivity and profitability? You’ve come to the right place. In this guide, you will learn about the top CNC plasma tables for small businesses in 2023 and how to make an informed purchase.

Best cnc plasma table for small business 2023

- Baileigh PT-22 CNC Plasma Table(Editor’s Pick)

- STV Motorsports Plasma Table (Best Overall)

- Baileigh PT-22 CNC Plasma Cutting Table(Budget Friendly)

- STV Motorsports CNC Plasma Table

1) Baileigh PT-22 CNC Plasma Table

Precision cutting is best with the Baileigh PT-22 CNC Plasma Table. This machine’s industrial components and steel frame ensure accuracy and durability. Its excellent CNC capabilities assure precise and consistent cuts. The PT-22’s precision exceeds expectations while working with thin sheets or heavy metal.

Durability and Strength

Since it was designed for tough cutting jobs, the Baileigh PT-22 is durable. It can handle tough materials because to its sturdy steel construction and high-quality parts. This commercial plasma table is durable and reliable.

User-Friendly Programming

Baileigh PT-22 programming is simple and versatile. This machine was designed for versatility. The user-friendly interface lets users of all ability levels build complex designs and perform difficult cutting operations.The PT-22’s programming approach lets you realise your creative ideas, whether you’re a pro or a beginner.

Affordable Solution

The Baileigh PT-22 CNC Plasma Table represents value. It cuts industrially but is affordable. Due to its affordability, it is the finest plasma table for businesses and individuals. Due to its longevity and performance, the PT-22 is a long-term investment.

Conclusion

The Baileigh PT-22 CNC Plasma Table exemplifies precise metal cutting. Due to its precision, robustness, user-friendly programming system, and pricing, this machine leads the field. The PT-22 is perfect for industrial cutters and hobbyists.The Baileigh PT-22 CNC Plasma Table revolutionises precise cutting.

Must Read – Best vpn routers for small business 2023

Baileigh PT-22 CNC Plasma Table First Hand Review Video

Video Source: Cycle QMX

Pros:

- CNC capabilities for precision cutting

- High-quality construction for durability

- Large working area for versatility

- Easy-to-use software for programming

- Compatible with a wide range of plasma cutters

Core Feature

| Manufacturer | Baileigh Industrial |

| Part Number | PT-22 |

| Item Weight | 500 pounds |

| Package Dimensions | 51 x 46 x 45 inches |

| Item model number | PT-22 |

| Color | Standard |

| Shape | Square |

2) STV Motorsports Plasma Table

The STV Motorsports Plasma Table allows you to easily handle huge metal sheets. This table provides space for little details and larger tasks. Due to its large working surface, it is perfect for many applications.

Superior Results Consistency

STV Motorsports Plasma Tables are precise and consistent. It cuts accurately every time, minimising material waste and improving project quality. Goodbye uneven cutting, welcome perfect designs. This table guarantees masterpiece cuts.

Superior Longevity

STV Motorsports Plasma Tables are durable. Since only high-quality materials were used, this table will survive. Due to its durability, it will work hard for you.

Easy Setup

STV Motorsports Plasma Table assembly is simple. The table comes with all parts and instructions for easy assembly. Your table will be operational quickly, letting you focus on your responsibilities.

Plasma Cutting Essentials

For advanced, reliable, and durable plasma cutting technology, the STV Motorsports Plasma Table is the best option. Businesses and industries choose it for its large working surface, stability, durability, and easy installation. The STV Motorsports Plasma Table will transform your metal cutting experience.

Must Read – Best vinyl cutter for small business 2023

STV Motorsports Plasma Table First Hand Review Video

Video Source: Orlando Sanchez

Pros:

- STV CNC Plasma Cutting Tables include top-notch technology and components.

- MANY USES: Our Windows-based CNC Plasma Cutting Machines may be used for many purposes

- Consistency and speed: High-accuracy stepper motors provide the STV CNC SPARX Series Plasma Tables speed, control, and consistency.

- USA-made, durable: Our tables can handle 3/4″ steel plates (and more).

- Lifetime support PACKAGE: 1 Year Warranty, Lifetime Customer Support, Setup and Installation Support, Tutorials and Videos, How-to Manuals

Core Feature

| Manufacturer | STV CNC |

|---|---|

| Item Weight | 450 pounds |

| Size | 4×8 |

| Style | SparX4800 |

| Material | Steel |

3) Baileigh PT-22 CNC Plasma Cutting Table

Its perfect alignment makes the Baileigh PT-22 CNC Plasma Cutting Table stand out. This ensures that every machine cut is straight and true. Whether you’re working on complicated designs or heavy-duty jobs, the PT-22 delivers precise results. Rework is avoided due to its precision.

Seamless Maintenance with Built-in Drain

The cutting table must be clean for best performance. The PT-22 has a convenient drain since Baileigh knows this. This smart innovation makes cleaning the table easier, maintaining smooth functioning and extending the machine’s longevity. You can maximise productivity with easy maintenance.

Industrial Flexibility

The Baileigh PT-22 CNC Plasma Cutting Table excels in a variety of industrial applications. This cutting table easily adjusts for metal fabrication, automobile parts, and bespoke signage. Its reliability and adaptability make it a vital tool for many industries, offering unlimited creative and productive possibilities.

Conclusion:

The Baileigh PT-22 CNC Plasma Cutting Table is reliable, accurate, and adaptable. Its industrial-grade construction and pre-assembly allow for easy use. The PT-22’s accuracy and built-in drain make maintenance easy. This cutting table’s compact size and versatility make it an essential tool for industrial success.

Unlock new precision and adaptability for your industrial projects with the Baileigh PT-22 CNC Plasma Cutting Table. Invest in this amazing equipment today for cutting quality like no other.

Must Read – Best vacuums for cleaning business 2023

Baileigh PT-22 CNC Plasma Cutting Table First Hand Review Video

Video Source: scrapingpavement

Pros:

- FULLY ASSEMBLED: Comes with correct alignment. No need to spend hours building.

- WATER BATH WITH BALL VALVE DRAIN: Collects dirt, debris, and smoke. It also helps keep the table cool.

- USER-FRIENDLY PROGRAMMING SOFTWARE: Includes BobCAD-Cam Express software.

- ACCURATE CUTTING: Fully-welded steel frame.

- SMALL FOOTPRINT: Accommodates shops with limited space.

- SMOOTH CUTTING: Industrial cable track on the X axis.

Core Feature

| Manufacturer | Baileigh Industrial |

|---|---|

| Part Number | 1006637 |

| Item Weight | 500 pounds |

| Package Dimensions | 51 x 46 x 45 inches |

| Item model number | 1006637 |

4) STV Motorsports CNC Plasma Table

STV Motorsports CNC Plasma Tables are versatile. This machine’s superior technology makes cutting easy. The STV Motorsports CNC Plasma Table excels at intricate designs and large-scale projects.

Consistent and Accurate Cuts

Cutting requires accuracy.The STV Motorsports CNC Plasma Table consistently cuts precisely. This machine makes precise cuts using cutting-edge technology and thorough engineering. The STV Motorsports CNC Plasma Table produces excellent results on delicate or thick metal sheets.

Lasting power

Plasma tables are expensive, thus durability is important. The STV Motorsports CNC Plasma Table is sturdy and made of high-quality materials. Professional fabricators and DIYers may trust this equipment to resist extensive use and tough operating conditions.

Best Workshop Option

The STV Motorsports CNC Plasma Table is perfect for any workshop or fabrication shop. Its adaptability, precision, and durability make it essential for cutting operations. This machine can improve your craftsmanship and creativity.

Conclusion

The STV Motorsports CNC Plasma Table is a cutting technology game-changer. Due to its advanced capabilities, versatility, and precision, this remarkable equipment delivers top-notch performance and quality. It’s worth it for cutting enthusiasts. Choose the STV Motorsports CNC Plasma Table for limitless cutting options.

Must Read – Best thermal label printer for small business 2023

STV Motorsports CNC Plasma Table First Hand Review Video

Video Source:Diamond J Customs, LLC

Pros:

- STV CNC Plasma Cutting Tables include top-notch technology and components.

- Our CNC Plasma Cutting Machines use Windows-based software (software package and licence included) for a variety of applications.

- STV CNC SPARX Series Plasma Tables use high-accuracy stepper motors for speed, control, and smooth operation, ensuring consistency and speed.

- Very Durable and Made in the USA: Our tables can easily accommodate 3/4″ steel plates (but can manage more).

- Lifetime support PACKAGE: 1-Year Warranty and Lifetime Customer Support, Setup and Installation Support, Tutorials and Videos, How-to Manuals

Core Feature

| Manufacturer | STV CNC |

|---|---|

| Item Weight | 400 pounds |

| Size | SparX510-5×10 |

| Style | SparX510 |

| Material | Steel |

Best cnc plasma table for small business 2023-Complete Buying Guide

This guide is designed to help small businesses who are looking to purchase a CNC plasma table. Technology has made great advances in the metal working industry over the past few years, and CNC plasma tables are becoming increasingly popular with small businesses due to their affordability and easy use. In addition, they help increase production speeds, accuracy, and flexibility in job shop manufacturing.

When it comes to selecting a CNC plasma table, there are several factors to consider including:

- Production capabilities

- Size of table and cutting area needed

- Required duty cycle of the machine

- Power source availability

- Accessories needed

In this guide we will discuss these various criteria and recommend which tables will fit your business’s needs best. We’ll also provide information about safety concerns when operating these machines as well as maintenance tips for your unit for optimal performance.

After discussing necessary criteria for selecting a CNC plasma table that fits your specific situation, we’ll list our top picks from various manufacturers based on each productive capability desired by typical small businesses just like yours. Hopefully by the end of this guide you have all the knowledge necessary for making an informed decision about investing in a proper piece of equipment that will maximize profitability now and well into future projects.

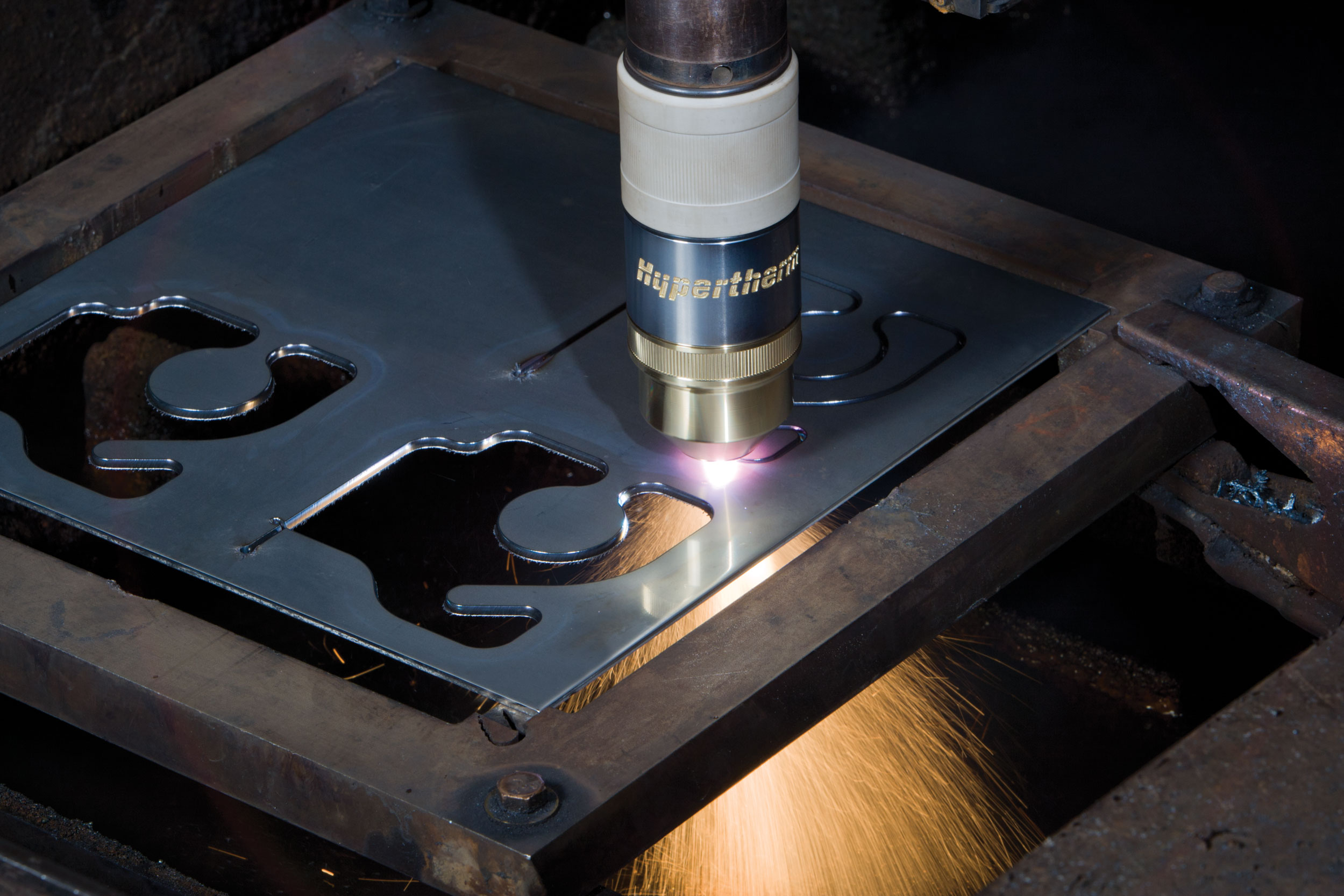

Photo Source: besttechnodynamics.in

Key Features to Consider

When shopping for a CNC plasma table, there are several key features to consider in order to ensure you have the right machine for the job:

- Size of Table – Tables come in a variety of sizes, from small tables that measure a few feet to larger industrial-sized models that measure ten feet or more. It’s important to choose a machine that will fit your workspace and offer you the size of cut that is best suited for the jobs you’ll be tackling.

- Cutting Speed – Different CNC plasma tables offer different cutting speeds, depending on the make and model. Be sure to ask about this when shopping for your table, so you can know how fast you’ll be able to get your project completed.

- Power Source – CNC plasma tables require a power source in order to operate. Most of these machines use either compressed air or oxygen as fuel sources; however, some can accommodate both sources simultaneously. Knowing what type of power source is necessary will determine which machine is best suited for your needs.

- Safety Features – Safety should always be at the forefront when operating any machinery and CNC plasma tables are no exception. It’s important to choose a model with safety features like emergency stop switches, automatic shut-off systems in case of fire or electric shock, and protective guards on moving parts in order to ensure everyone working near the machine stays safe while it’s running.

Cutting Area

The cutting area is one of the most important factors to consider when selecting a CNC plasma table for your small business. As a general rule, the cutting area should be large enough to accommodate the average size of your job. If you plan on creating larger pieces or smaller detailed pieces, then the cutting area size may need to be adjusted accordingly.

However, purchasing a machine with a larger working area than needed could mean additional maintenance costs and decreased run times due to extra space that needs to be heated up before cutting. Additionally, some CNC plasma tables require pre-configured table sizes and obstacles like safety fences to work properly, so make sure you check these specifications before making your purchase.

Torch Height Control (THC)

Torch Height Control (THC) is an important system that plays an essential role in the performance of a CNC Plasma Table. This system will quickly and automatically adjust the height of the cutting torch to ensure that it’s always at the appropriate elevation for efficient and accurate cutting. The THC system is a feature that should not be overlooked, as it could have a big impact on your overall production costs.

When selecting a CNC Plasma Table, you’ll need to consider factors such as:

- Voltage tolerance,

- Maximum current capacity, and

- Speed of response.

Higher voltage tolerance will enable your machine to run more efficiently even when presented with variable power levels. The maximum current capacity will determine how much amperage can be supplied to the process and ultimately affect its performance. Finally, a faster speed of response means the table can quickly detect changes in workload or other factors and adjust accordingly. All of these factors combine to reduce operating cost and enhance productivity – vital components in any small business!

Table Configuration

When it comes to shopping for a CNC plasma table, one of the most important things to consider is table configuration. The plasma table’s cutting surface will vary in size depending on the model you choose, and the overall structure of the table itself may also be unique. The number and size of torch holders and covering materials also vary between models. Here are some of the main factors to consider when evaluating different plasma cutter tables:

- Table Size: Generally, CNC plasma tables come in a variety of sizes ranging from small tabletop models to large models that take up several feet of floor space. You’ll want to select a model that fits within your available space while still providing enough room for your cutting needs.

- Number Of Torches: Most modern CNC plasma tables feature from two to eight adjustable torches, allowing you get twice as much cutting done faster than with conventional single-torch systems.

- Covering Material: High-quality CNC plasma tables often feature robust stainless steel covers for protecting against ash or other debris during cuts. These covers can help with maintaining accurate laser calibration over long periods of time, ensuring consistent precision cuts every time you use your machine.

Plasma Source

The plasma torch is the device used to generate the plasma needed to cut metals. It is powered by a DC or AC power source, and when it comes in contact with electrically conductive gases such as oxygen, nitrogen, argon, hydrogen and acetylene a high-temperature arc is created. Depending on the type of metal being cut, different pressures and gas mixtures can be used.

In addition to this, other consumables must also be taken into account such as nozzles and electrodes which help regulate the plasma stream for efficient cutting results. The distance between nozzle and work piece – known as the standoff – is carefully controlled to get maximum cutting performance from your machine.

It’s important to match your needs with what a given source can deliver: focus on speed and power when using thicker materials that require higher amperages while keeping an eye on finer details with thinner sheets that require lower amperages.

User-friendly Interface

The user interface is one of the biggest factors you need to consider when buying a CNC plasma table for your small business. Many CNC plasma tables offer features such as intuitive touch-screen programming and advanced settings that allow you to customize various aspects of your cutting projects. You should look for a model with a user-friendly, straightforward interface that allows for both quick setup and trouble-free operation. This will help ensure that your team can easily gain proficiency in using the machine, expedite setup and allow you to focus on more important aspects of the cutting process.

Additionally, it is beneficial to look for a machine with built-in safety features to protect against any potential damage or injury while operating the machine.

Maintenance and Upkeep

Maintenance and Upkeep are a critical factor in the longevity of your CNC plasma table. It is beneficial to inspect the machine regularly for any signs of wear and tear or potential problems that may arise with heavy usage. Proper maintenance ensures efficient operation and improves the overall return on investment of your equipment. Once you have selected your perfect CNC plasma table, it will be necessary to follow a few key steps to ensure optimal performance:

- Keep the work area free from dust or debris as these can impede operation;

- Add fluids (coolant, oil etc.) according to manufacturer’s instructions;

- Check components weekly for signs of wear or any other irregularities;

- Ensure that any electrical connections are secure and all bolts are tight;

- Utilize the recommended lubricants in order to avoid premature degradation;

- Replace damaged parts immediately to prevent further damage from occurring.

Adequate maintenance is essential for keeping your CNC plasma table running efficiently for many years. Taking care of your machine will help it last much longer than expected and ensure minimal repairs down the line. In addition, an organized workspace helps reduce waste and helps keep operations running smoothly.

Importance of Regular Maintenance

Regular maintenance of your CNC plasma table is essential to ensure optimal performance and a longer lifespan. If you’re a small business, regular maintenance can save you a great deal of money in the long run. Below are some of the most important aspects of regular maintenance that you should consider when maintaining your CNC plasma table:

- Inspect the Plasma Table and Components: It’s important to inspect all parts of your plasma tables for any signs or wear and tear or damage, such as loose bolts or worn components. Additionally, be sure to check all cable connections for possible fraying or deformation, which can cause interruptions in functionality.

- Replace Parts and Accessories: As part of regular maintenance, it’s important to replace key components such as belts, pulleys, consumables and other parts that may become worn with usage or time. For certain key components such as relays and switches, preventive replacements can often be completed before any damage occurs due to age by having spare parts on hand at all times in order to ensure optimal performance levels regardless of strain put on the machine.

- Clean Machine Components and Environments: If dirt is allowed to accumulate inside and outside the machine due to inadequate cleaning schedules it can cause various issues over time resulting in poor performance levels when not addressed properly. Be sure to clean both external areas as well as internal components such as wipes rotary belts regularly in order maintain good hygiene levels while operating a plasma cutter safely.

- Re-Level Machine As Needed: Depending on usage size and scope it may be necessary periodically re-level the machine for optimal performance results particularly when dealing with precision cutting operations or intricate jobs over long periods of time that require consistent results without fail over different batches even after frequent use intervals have elapsed during peak production seasons within any given calendar year etcetera.

Recommended Maintenance Practices

As with any mechanical system, regular maintenance is recommended for any CNC plasma table to make sure it is running correctly and safely. Below are some of the basic practices that should be followed on a regular basis to maintain a CNC plasma table:

- Lubricate moving parts – It is important to periodically check and if necessary lubricate moving parts on the CNC plasma table in order to ensure that they do not experience unnecessary wear and tear. Proper lubrication of joints will help ensure longevity of the equipment and extend its life expectancy.

- Monitor consumables – Plasma consumables such as electrode, nozzle, shield cap and retention caps must be replaced as they become worn or when they no longer meet specifications determined by the manufacturer’s operational guidelines. Keep track of which consumables have been used as well as when they should be replaced.

- Check torch alignment – Alignment should be checked periodically by measuring across the endpoints of an arc compared to the center point of a round piece, or by plotting a well-known linear pattern such as X-Y-X-Y over multiple locations or surfaces to check for problems with accuracy due dragging or machine setup issues. It is also important to visually inspect for any performance degradation or improper operation from time to time which can affect cut quality in terms of threading accuracy and/or possible slug pulling that could lead to long torch runout delays causing inaccurate cuts.

- Review safety measures – The safety protocols in place at a manufacturing facility should be regularly reviewed and enforced so that operators understand their responsibilities while using the CNC plasma system safely without putting themselves at risk or otherwise damaging the equipment due lack of knowledge on proper usage protocols.

Photo Source: fabricatingandmetalworking.com

Upgradability

When purchasing a CNC plasma table, consider the possibility of needing to upgrade your machine’s system due to changes in the market. Factors like increased material volume and additional cutting speed can be improved on with an upgraded system. If so, never overlook investing in an upgradable product.

The main components of a CNC plasma table that may need upgrading are the CPU and software packages used for operating the machine. It is important to make sure that with any upgrades you are also taking into account features such as precision, speed and accuracy as well as any other important factors specific to your shop’s individual needs.

It is a good idea to research products available both at the time of your initial purchase and those that may be introduced at a later date should an upgrade be needed. Make sure you have planned ahead for problems or changes which could require an upgrade by considering them in your purchasing criteria up front.

Conclusion

CNC plasma tables are an excellent tool for small businesses that need a cost-effective way to produce high-quality parts and products. While there is no “best” CNC plasma table for all applications, there are many different models available to meet the needs of any small business. With careful consideration of budget, size, features, and local tech support, you can find the best CNC plasma table for your particular requirements.

When researching potential tables, it’s important to look at reviews from previous customers as well as technical specifications. You should also consider the amount of time you have available to learn how operate the machine and its software. Taking into account these factors will help ensure you purchase a CNC plasma table that fits your needs perfectly and allows your business to maximize its work efficiency and create quality goods.

FAQ’s

What should I look for in a CNC plasma table?

You should look for a CNC plasma table with a sturdy frame, reliable motion control, accurate cutting capabilities, adequate cutting area, and a user-friendly control system.

How much money can you make with a plasma cutter?

The amount of money you can make with a plasma cutter depends on the volume and type of work you do, and the amount you charge per hour.

How long does a plasma table last?

The lifespan of a CNC plasma table can vary, but with proper maintenance and usage, they can last several years.

How accurate are CNC plasma tables?

The accuracy of a CNC plasma table depends on various factors, including the quality of the machine, the motion control system, and the level of operator skill. High-end plasma tables can produce very accurate cuts, typically within 0.5mm.

Can you make money with a CNC plasma table?

Yes, you can make money with a CNC plasma table by offering cutting services to others or by creating and selling custom metal products.

What is better than a plasma cutter?

Alternatives to plasma cutting include laser cutting, water jet cutting, and oxy-fuel cutting. The best option depends on the type of material you’re cutting and the desired cutting speed and accuracy.

How much does plasma cutting cost per hour?

The cost of plasma cutting per hour depends on several factors, including the cost of consumables, electricity usage, and operator wages. It can range from $50 to $150 per hour or more.

Is plasma cutting cheaper than laser cutting?

The cost of plasma cutting is generally lower than laser cutting, but the two methods have different strengths and weaknesses, and the best choice depends on the specific cutting requirements.

What can I make and sell with a plasma cutter?

With a plasma cutter, you can make and sell a wide range of metal products, such as signs, art pieces, custom automotive parts, and more.

How much does plasma cutting cost?

The cost of plasma cutting depends on several factors, including the cost of the machine, consumables, and electricity usage. A high-end CNC plasma table can cost several thousand dollars, while consumables and electricity usage can add several hundred dollars per year.

Sidney Reed is an accomplished entrepreneur, author, and CEO of a smallbusinesssuccessroadmap.com and informative website. With over 20 years of experience in the business world, Sidney is dedicated to helping small business owners succeed. He has written several best-selling books on small business ownership and is a sought-after speaker and contributor to business publications. Through his small business equipment reviews and informative website, Sidney and his team provide valuable information and resources to help small business owners make informed decisions about equipment purchases.