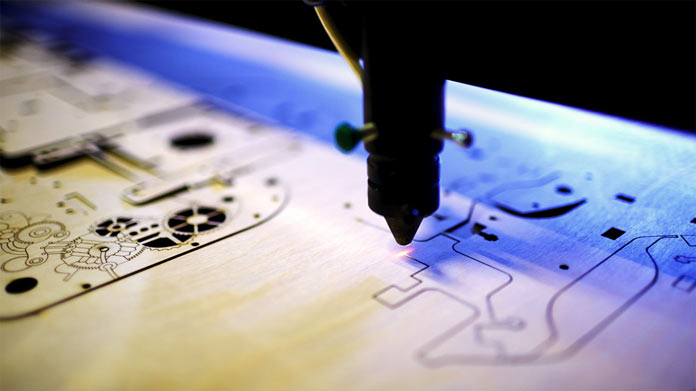

Curious about laser cutters and how to maintain them? You’ve come to the right place. Whether you already own one or plan to buy a laser cutter for your small business, this guide will provide all the necessary information.

We’ll show you how to maximize the lifespan of your laser cutter, with easy steps and maintenance tips that anyone can do.

This guide is intended to provide an overview of proper maintenance for laser cutters used for small businesses. Laser cutters are powerful tools in helping to create precise and accurate designs. However, like any other machinery, laser cutters require maintenance in order to work efficiently and safely.

The first point to remember when it comes to maintaining your laser cutter is that regular maintenance and cleaning of your machine will help maintain its performance over extended periods of usage. This means regularly inspecting the parts, such as mirrors and lenses, as well as checking and cleaning the gas supply system. Additionally, accuracy should be checked and maintained through proper guidance systems, focusing components, and cutting parameters in order to ensure the highest quality of output when cutting with a laser cutter.

The next consideration when it comes to maintaining your laser cutter is safety measures that can be taken while operating it. Protecting both the operator, any bystanders or workers in the vicinity of a working cutter must be observed at all times. Wearing appropriate gear such as eye protection or face masks should not be overlooked if running a machine with potential dangers attached; unsafe use can lead to serious injury if careless mistakes are made. Alongside wearing protective equipment, operators should follow manufacturer instructions for safe operation of their equipment at all times.

Importance of maintaining a laser cutter for small businesses

For small businesses, discovering a cost-effective solution for a wide range of industrial tasks can be a difficult pursuit, with laser cutters often perfect for the task. If used and maintained properly, these tools can be an invaluable asset to a business’ operations, allowing them to complete tasks accurately and rapidly that would have taken many hours by other methods.

Not understanding the importance of regular maintenance on laser cutter machines can lead to disastrous results that may include: decreased accuracy in cuts, increased risks of chronic equipment malfunctioning and malfunctions that could cause permanent damage if not attended to. To get the most out of your laser cutter you will need to develop a regular maintenance schedule and follow it with precision.

Firstly, it is important to ensure you regularly clean the optics and mirrors in your machine. These are vital components responsible for keeping the beam alignment true when cutting materials – dirt or grime left on these surfaces will cause the optical path length between mirrors and laser tube corrupt what’s known as ‘optical return loss’ which means imprecise beam quality and alignment when cutting.

In addition it is important to check calibration settings frequently – this consists of checking over all X, Y & Z axes axially every so often or after any large parts have been cut won/ extended i.e for proper lenses focusing correctly or any other mechanical piece needs adjusting periodically (i.e lens mounts). It is also important to align focus lenses at least once per quarter or monthly depending on use frequency. In some cases you may find dust trapped behind lens mounts during re-alignments requiring professional cleaning from an engineer.

Finally – being mindful of your environment is imperative, in terms of humidity levels within working area as well as lack exposure & contact with both dust particles inside hood enclosure as well exterior atmosphere. Too much dust exposure may settle on components within hood causing material adhesion onto lense mount parts thus leading too effects such irregular beam quality & unintentional ignition while cutting certain heat sensitive materials etc.

Benefits of regular maintenance

Regularly maintaining your laser cutter will ensure that it performs up to its full potential for as long as possible. Keeping up with regular maintenance will bring a host of benefits, including:

Increased efficiency – Regularly cleaning and servicing your machine ensures it can work at its optimum levels at all times, allowing you to get more done.

Increased lifespan – Maintenance and timely replacement of parts keeps the various components running in top condition and provides ultimate protection against potentially damaging wear and tear.

Improved safety – Replacing worn parts helps to prevent hazards, including electric shock and accidents which can result from malfunctioning equipment.

Reliable performance – Anticipating issues is much easier with a machine that receives regular attention; knowing what needs to be done makes daily operations smoother.

Understanding Your Laser Cutter

Laser cutters can provide small and medium business owners with the precise cutting solutions they need in order to produce products quickly and accurately. It is important to understand the different components of a laser cutter before attempting operation, in order to ensure safe and effective use.

The main parts of a laser cutter are the power supply, cutting head, cooling system, feeder mechanism, bed assembly, and control system. Each component needs to be maintained for proper functioning.

The power supply of a laser cutter is responsible for generating high voltage electricity that drives the machine’s laser beam. It must be tuned correctly in order to deliver the appropriate amount of energy for each specific application. The cutting head is where the cutting action takes place; it contains the physical elements that house and guide the laser beam as it processes work material. The cooling system helps regulate temperatures within the working environment while also keeping air inside cool enough so that all components remain operational without risk of overheating or damage due to rapid temperature changes.

The feeder mechanism supplies sheets or other materials into the cutting chamber in order for them to be processed by the laser head; it must remain lubricated correctly and only accept materials that are compatible with its specifications in order for it operate accurately without malfunctioning. The bed assembly is concerned with supporting materials so they do not shift during processing; while this part may remain stationary during some applications, it should always be checked regularly for wear or skew settings since an uneven surface can cause cuts to become irregular and inaccurate over time. Finally, the control system allows users to input commands into their machine which will initiate actions from other parts within; this must be kept up-to-date as new technologies become available in order for operations to run smoothly throughout its life cycle.

Components of a laser cutter

A laser cutter for small business is an invaluable tool for any business owner. It can be used to quickly and accurately cut a wide variety of materials, from paper to plastic and even metal. Before you can use this valuable tool, it’s important that it’s properly maintained so you get the most out of its life and performance. This guide will walk you through the components of a laser cutter and how to maintain them.

Laser tube The laser tube is responsible for generating the laser beam that cuts your material. It is made up of sealed-off glass and contains two gases: Xenon and Helium-Neon (HeNe). The Xenon gas acts as an energy source when electricity is applied to the system, creating a current that produces laser light by exciting the HeNe gas within the tube. This combination creates intense heat which helps it create a fine beam quality, ideal for cutting materials precisely with high speeds. To maintain your laser tube, make sure to check it regularly for any signs of wear and tear or blockage caused by dust particles in the tube’s vacuum pumps or filter. You should also regularly clean dust off these pipes as well as coolant systems connected to your laser tube, or have a technician do them if necessary, as they can conduct regular maintenance on these elements of your machine too.

Focusing lens optics For high-quality results when engraving or cutting material with a laser cutter, having optimally aligned optics such as focusing lenses is essential. The focal lenses work in conjunction with each other—the first lens focuses only one plane while the second one focuses on all planes—to direct ultraviolet light onto metal surfaces allowing them faster method in engraving; then produce precise etched marks without applying an excessive amount of heat which could potentially damage delicate objects being engraved on metal surfaces.. To properly maintain your optics lenses ensure that there are no light leaks due to dirt accumulation inside them by cleaning off debris from their surfaces regularly through controlled air pressure devices.

Regular Maintenance Procedures

Regular maintenance of your laser cutter is important in order to ensure it runs optimally and remains in good condition. Below are the recommended maintenance tasks that should be carried out at least once a month:

- Clean the machine by removing all dust and debris from inside and outside the machine, including within areas such as nozzles.

- Clean lenses with lens cleaning paper or aerosol lens cleaner oruse microscope wipes for cleaning lenses if indicated by the manufacturer’s instructions.

- Check connection cables are securely fastened, and not frayed, cracked or obstructed in any way that could interfere with a correct electrical contact.

- Check all switches are securely tightened, functioning correctly, and lubricate components if necessary per manufacturers instructions.

- Replace worn or damaged lenses as soon as possible to ensure maximum performance of your machine

- Measure machine alignment every six months using internal reference marks if available, or moveable fixtures for checking mechanical accuracy of workpiece positioning accuracy and repeatability capabilities of your device per manufacturers instructions; align optical systems where specified by manufacturer’s instructions; use standard instruments such as autocollimators for accurate measurements of fractional wavelengths of light passing through an optical system; align mirrors against each other for accurate displacement control of laser beam position on workpiece

Daily maintenance tasks

A key part of successful laser cutting is daily maintenance. Performing a few simple tasks each day can help keep your laser machine running in peak condition for years.

Daily maintenance tasks include clearing debris from the channel, checking ventilation and cooling systems, inspecting the protective housing and more. Here are the main activities you should be aware of when caring for your laser cutter:

- Clear debris from the channel: Any debris in the channel can cause major issues with your cutter, which is why it’s important to clear out any debris that may have collected over time. Use a vacuum or compressed air to remove dust, dirt and other small particles that may be blocking airflow or impeding proper operation of your machine.

- Check ventilation and cooling systems: Your machine’s ventilation system should be checked at least once per day to ensure that it is functioning properly and providing adequate cooling to prevent overheating and damage to internal components. It is also important to check all filter elements, pressure pumps, fans and exhaust hoses on a regular basis.

- Inspect protective housing: Regularly inspect the protective housing around the cutting area for damage or any modifications needed that could improve safety or operation of the machine. Be sure all doors close properly with no openings around hinges or brackets where fingers could get caught during operations.

- Test auto-focus feature: Test this feature regularly to ensure accurate focusing on all materials used in production processes before setting up job parameters for cutting thick material or thicker than usual stock material. Through testing you might determine if you need finer adjustments that can only be made manually for sheet metal material thicknesses thinner than 1/16 inch (0.0625″).

Weekly maintenance tasks

Weekly maintenance tasks are just as important as daily maintenance and are designed to limit major issues that necessitate expensive repairs later on. Here is a list of tasks you should do each week:

- Inspect the laser tube electrical connection and vacuum hose cover – Make sure the laser tube electrical connection is well-attached, with no loose wires, and the hose cover is securely fastened.

- Check dust filters – Many dust filters need to be replaced at least once a month; inspect it for signs of clogging or damage and replace it when needed.

- Clean lens and mirror surfaces – Remove any build-up of soot or dirt on lens and mirror surfaces using an appropriate cleaner, such as isopropyl alcohol (IPA).

- Visually check alignment – Regularly check the laser beam focus distance from the material surface using the manual focus sights on your laser cutter’s control board; any adjustments may need to be addressed by a technician.

- Dynamically check alignment – Use specific aligned targets for focused beam tests; an improper beam can lead to lower cutting quality or even cause safety issues with flammable materials in your shop environment if left unattended for too long.

- Assess speed – Make sure your machine’s speed settings remain optimal while you cut various materials by checking against charts provided by manufacturers outlining speed vs power settings for different thicknesses of materials being cut in order to maximize efficiency rates while keeping scrap rate very low.

Monthly maintenance tasks

To ensure consistent and reliable performance from your laser cutter, there are a few monthly maintenance tasks that you should perform. The following list contains the most important tasks:

- Clean exterior: Wipe down the outside of your laser cutter with a damp cloth or an antistatic cleaner once per month. Make sure to pay special attention to the vent areas and exhaust fan. This will keep dust and particles from building up on the exterior surface, impacting performance or increasing chances of failure over time.

- Check hoses and connections: Inspect hoses connecting the laser power supply to the cutting head for any signs of wear or cracking, replace if necessary as soon as possible so that air compression is not lost during cutting operations

- Manually feed material through: Use a test piece of material each month to make sure it can easily travel through your machine without hesitation or sticking points along its path.

- Calibrate lasers: Open calibration software located in your laser machine’s menu settings, manually adjust settings for focus displacement, beam quality detection, and duty cycle parameters. Check these settings every month to ensure optimum accuracy and precision for accurate cuts.

- Replace lenses: Replace lens assembly parts every 3-6 months depending on manufacturer’s recommendations to ensure sharp edges on cuts with no signs of burning or burring along edges.

Conclusion

The maintenance of your laser cutter is essential for ensuring its optimal performance and longevity. This guide has highlighted the critical factors that you should consider in its upkeep, including regularly checking the optics, calibrating and prioritizing airflow, cleaning your machine parts, changing consumables when necessary, and keeping your software up to date with relevant updates.

Additionally, it is important to store the machine properly in a clean and dust-free area. Finally, familiarizing yourself with the working principle of your laser cutter will enable you to make informed decisions that ensure maximum efficiency when carrying out repair or larger projects.

By following the guidelines outlined in this guide, you will be able to maintain a safe and healthy laser cutter while receiving the best possible output from it.

FAQ’s

How do you maintain a laser cutter?

To maintain a laser cutter, you should regularly clean the lens, mirrors, and other components, check and replace the coolant, lubricate the moving parts, and keep the work area free from debris.

What are 5 safety issues we need to do when using the laser cutter?

Five safety issues to consider when using a laser cutter are wearing appropriate personal protective equipment, ensuring proper ventilation, avoiding combustible materials, securing loose clothing and jewelry, and not leaving the machine unattended while in use.

How often should a laser cutter be serviced?

A laser cutter should be serviced at least once a year, or more frequently if it is heavily used or shows signs of wear and tear.

What are 2 disadvantages of a laser cutter?

Two disadvantages of a laser cutter are that it can be expensive to purchase and maintain, and it may not be suitable for cutting some materials.

How many hours does a laser cutter last?

The lifespan of a laser cutter can vary depending on usage and maintenance, but a well-maintained machine can last for thousands of hours.

What is the biggest safety issue with lasers?

The biggest safety issue with lasers is the risk of eye damage from direct or reflected laser beams.

What is the biggest hazard with using lasers?

The biggest hazard with using lasers is the potential for fire or explosion if the beam comes into contact with flammable or explosive materials.

What are laser safety best practices?

Laser safety best practices include wearing protective eyewear, ensuring proper ventilation, using caution when working with reflective surfaces, and following all manufacturer guidelines and safety procedures.

Do laser cutters use a lot of electricity?

Laser cutters can use a significant amount of electricity, especially if they are running for long periods or at high power settings.

How long does a laser cutter tube last?

The lifespan of a laser cutter tube can vary depending on usage and maintenance, but it typically lasts for several thousand hours before needing replacement.

See Also :

- Best lawn mower for business

- Best projectors for business

- Best screen printing machine for small business

- Best smartboard for business

- Best backpack for business travel