Are you a small business looking to save time and money? A laser cutter could be the perfect answer.

You need to know how to select the best laser cutter for your needs, however. This guide will help you find the perfect fit for your small business.

Welcome to this guide on laser cutters for small business owners. Whether you have been running a business for a few years or you started your business recently, investing in the right equipment is key to success. If you’re looking for an efficient way to complete tasks such as cutting shapes and engraving objects, a laser cutter may just be what you need. With the right information and guidance, it’s possible to make an informed decision about which type of machine fits your needs best.

Before making any purchases, it is important to have a good understanding of exactly what laser cutters do and the advantages they can provide your business. This information can help you make an educated choice when selecting the product that will serve your needs in the most effective manner. Within this guide, we will cover some of these topics by addressing questions such as:

-What are the different types of laser cutters available? -What should I consider when buying a laser cutter? -What safety precautions should I take when using a laser cutter?

We hope that with this resource, small business owners can make sound decisions on their investments in equipment and become familiar with how best to use them properly and safely. After reading through this guide fully and considering all questions presented, small business owners will be ready to invest confidently in the best machine for their specific needs.

Definition of Laser Cutter

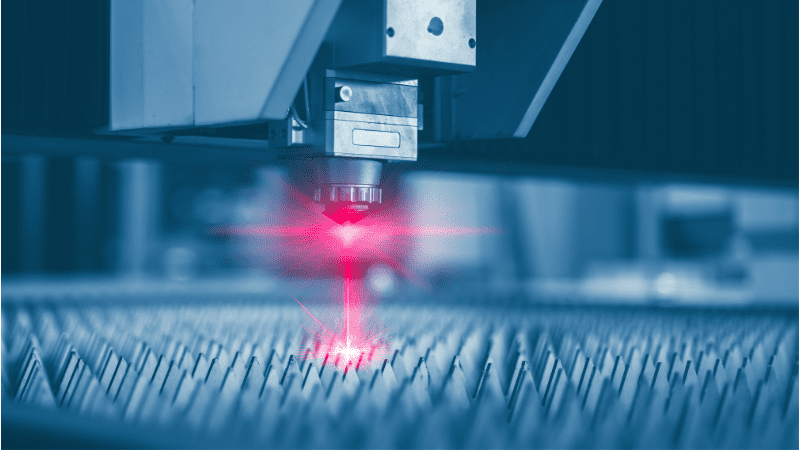

A laser cutter is a machine that uses a laser to cut and engrave materials with precision. It is extremely versatile, as it can be used to cut, engrave, and/or mark all kind of materials like wood, metal, acrylic glass, stone and paper. Additionally, this technology enables a wider range of artwork designs like intricate shapes and detailed logos.

Laser cutters are found in a variety of sizes and power depending on the type of projects they are required for. For example 3D printers might require more power but could work with relatively low levels of precision. On the other hand more complex crafts demand higher levels of precision which will require a more powerful laser cutter.

Overall, it is important to consider your specific needs when choosing the right model for your business purposes; factors such as size requirements and versatility need to be taken into account when choosing the best laser cutter for your small business or organization.

Importance of Laser Cutters for Small Businesses

Small businesses can benefit greatly from the use of laser cutters to streamline their production processes. Laser cutting is a precise technology that enables fast and accurate fabrications. It offers one of the highest levels of precision, ensuring that you get precisely designed components with minimal waste material and consistently high-quality production runs.

Laser cutting also provides a great way to differentiate your products in the market. Whether it’s intricate patterns or complex shapes created by computer-guided lasers, you can create unique customized parts with unparalleled detail and accuracy. The use of this technology also allows small businesses to produce shorter production runs at lower costs than traditional manufacturing techniques such as stamping or extrusion.

Finally, laser cutters provide an excellent digital workflow to quickly turn ideas into products, helping small businesses stay ahead in rapidly changing markets by bringing new products to market quicker than ever before. Laser cutting makes it easy for business owners to realize cost savings and significantly reduce lead times, allowing them to focus on customer satisfaction rather than just producing large quantities of standard parts.

Factors to Consider when Choosing a Laser Cutter

Choosing the best laser cutter for your small business requires research and consideration of certain factors. Laser cutting technology is highly sophisticated and efficient, so you should make sure to take into account each element that can affect performance and usability. Here are some key points to consider before making you purchase:

-Your Budget: Set a realistic budget for your machine; consider training costs, software packages, supplies, maintenance needs and more.

-Your Geographical Location: Look at the local regulations in your area when buying a laser cutter as some states may have more stringent rules than others.

-The Kind of Work You Need It For: Know what type of materials will be cut most often with the machine such as cardboard and paper goods, plastic parts or metal plates. This can help you determine which type of laser cutter will best suit your needs.

-Safety Features: Be aware that these machines need to be operated with extra care due to the potential hazards they present; check for appropriate safety features before choosing a model.

-Ease of Use & Maintenance: Make sure the model chosen is easy to use and doesn’t require complicated maintenance procedures every time something goes wrong or wears off.

-Software Compatibility: Consider if the laser cutter is compatible with any programs or software you may require for work purposes e.g., CorelDraw, Adobe Illustrator etc .

-Warranty & Service Support : Check for support options such as warranties, maintenance contracts and spare parts availability from the manufacturer or service provider before purchasing a machine.

Material Compatibility

If you’re looking for a laser cutter to help boost the operations of your small business, it’s important to do your research and determine which machine best suits your needs. Material compatibility is one of the key factors that should be considered before purchasing a machine. Every type of material requires different parameters and settings for the laser cutter to work efficiently and safely, so it’s essential to review the materials that the chosen machine is compatible with.

Some common materials used in small businesses are wood, acrylic plastic, card stock, felt, foam board and fabrics. While many laser cutters can accommodate multiple types of materials, some may only be restricted to specific ones. It’s important to double check each specification manually or contact professional representatives from the company who will provide information about materials that can be used with their specific machines. For safety reasons, users should also ensure that all equipment is rated for use with these materials before using them in the process of cutting or engraving.

Cutting Speed and Accuracy

A laser cutter’s cutting speed and accuracy depend on the power of its laser, its speed and acceleration capability, as well as its material selection. A higher wattage will usually result in faster cuts but with less accuracy, so the wattage must be taken into account when choosing a laser cutter for your small business.

Most laser cutters on the market these days are capable of cutting speeds between 0–2000 mm/s (or 0–78 inches/s). While this is more than enough for most standard materials like wood and paper, speeds need to be increased substantially when cutting thicker or denser materials like metal or stone. The best way to find out a laser cutter’s true capabilities is by testing it out with different materials. Additionally, lower-power lasers may struggle to achieve consistent results due to their weaker beam strength.

Accuracy is another important factor to consider when shopping for a laser cutter. It’s measured in nanometers and will affect how precise the beam is able to cut at various speeds and depths. The majority of machines offer an average accuracy ranging from +- 1nm up to +- 25nm which should be more than enough for most tasks common among small businesses. However professionals may require greater precision which can usually achieved through higher-end models or devices made specifically for that purpose.

Understanding Laser Cutter Features

It can be easy to get overwhelmed by the various features offered by laser cutters, but knowing which ones are essential and which ones are not will help you to make an informed decision. Generally speaking, there are five main components that should be taken into account when considering a laser cutter for your small business: speed, accuracy, customization options, power settings, and cost. Below, each of these components is outlined in more detail.

Speed: This feature describes how quickly a laser cutter can cut or engrave materials. Most machines come with adjustable settings that allow users to adjust the speed depending on the material they are using and their desired results.

Accuracy: Accuracy refers to how precise a laser cutter can be in terms of cutting shapes and angles. Most machines come standard with adjustable settings that allow users to get very precise measurements and cuts.

Customization Options: Some laser cutters come with additional features that allow users to customize their designs such as adding color or different effects like etching or embossing on materials.

Power Settings: This feature describes how much power can be used for a given task by the machine, as well as its ability to work for extended periods of time without overheating or damaging sensitive materials like fabric or paper.

Cost: Depending on the model you choose and its available features, laser cutters will range greatly in price from several hundred dollars for entry-level models up to several thousand dollars for advanced models with additional features like water-cooled systems for extended use and high-precision optics built in for increased accuracy at higher speeds.

Bed Size

When it comes to choosing the right laser cutter for a business, one of the most important considerations should be bed size. The size of the bed will determine what size and thickness you will be able to engrave or cut. For example, some laser cutters may have a maximum cutting size of only 12×20 inches (30×50 cm) or smaller, while others can go up to 24×40 inches (60×100 cm).

The larger the bed size, the wider your range of materials you will be able to process and fewer restrictions on job sizes, which makes it perfect for businesses with high production demands. In addition, if your business is creating large items with intricate designs or detailed artworks, a larger bed will also make positioning more flexible.

Another factor related to bed size is beam spot size. The beam spot determines how precise and finely detailed your engraving/cutting can be. A small spot size allows for very accurate cuts with 0.006-inch (0.1 mm) resolutions in some models, while larger spots produce more coarse cuts that are suitable for thicker materials such as wood and acrylics. When looking at potential machines, be sure to take into consideration both their cutting area and beam spot sizes.

Software

Software is a critical component of any laser cutting setup. Different software packages will have different user interfaces, capabilities and support options, so it’s important to look into what each one has to offer when choosing the best system for your small business.

When looking into laser cutting software, you should consider the user interface and comfort level of the software. The last thing you want is to waste time trying to learn how to use a complicated program. It’s also important to think about the capabilities of the software like nesting, 2D/3D CAD design integration, laser job queueing and more. Additionally, be sure you can get help if you need it; look into third-party technical support options or think about selecting a model that can work with an onsite technician.

Exhaust and Filtration System

Cleaning and maintaining an exhaust system for your laser cutter is essential for successful and effective operation. The exhaust and filtration system, known as “fume extraction,” is responsible for removing harmful gases from the work area such as fumes from fiber materials or melting plastics, as well as smoke and particles from engraving. Without the proper exhaust and filtration system, the environment can become unsafe to work in due to airborne particles created in lasers operations.

When shopping for a laser cutter for your small business, it is important to take into consideration what type of fume extraction this machine offers. Look at how powerful the system is and if it meets local safety requirements before making a purchase. The Basic Requirements look at are: Airflow Capacity/CFM flow rate; Filter Type; Cleaning features; Exhaust Port size & Positioning; Noise level rating; Self-Monitoring System (if available).

Airflow capacity measures how much air passes through the filter of the laser cutter per cubic foot per minute (CFM). It must be adequate enough depending on its working area size to capture any fumes produced by operations. It heavily depends on the type of material being cut or engraved on. Fiber materials create more hazardous fumes that need considerable extractor power while solid metals require less intense extractors. Check that ventilation vents are large enough in diameter to insure proper airflow rate passing through filter media. Have an engineer calculate exact CFM needed based on room size/dimensions prior purchase if possible! In most cases an exhaust hood over this device will do wonders at suctioning up deleterious substances thus promoting overall health and safety standards for you & your employees!

Conclusion

In conclusion, it is important to analyze your small business needs before investing in a new laser cutter. You should carefully weigh the size of the machine and its capabilities with the cost and space available to you. All these factors are relevant to make an informed decision that allows your business to flourish while making use of the latest advances in technology.

Furthermore, you should ensure that consumables are readily available and compatible with existing equipment in order to have a smooth running operation. In addition, always remember to consider safety guidelines when operating laser cutters as they can be dangerous if not handled properly.

Ultimately, if you know what you need and remain mindful of all necessary considerations for your small business, then selecting the best laser cutter for your needs can be a rewarding choice!

FAQ’s

How do I choose a laser cutter?

Choosing a laser cutter depends on several factors like material type, thickness, power requirement, workspace, budget, and maintenance.

What is the best laser engraver to start a business with?

The best laser engraver to start a business with depends on your business requirements, budget, and the type of material you want to engrave. Some popular options include the Glowforge Plus, Boss Laser LS-1416, and the Dremel LC40-01.

How powerful of a laser cutter do I need?

The power requirement of a laser cutter depends on the thickness and type of material you want to cut. For example, a 40W laser cutter is suitable for cutting thin materials like paper or acrylic, while a 100W laser cutter is more suitable for cutting thicker materials like wood or metal.

What are 2 disadvantages of a laser cutter?

Two disadvantages of a laser cutter are high initial investment cost and potential safety hazards if not used properly.

What is the best type of laser cutter?

The best type of laser cutter depends on your specific needs and requirements. CO2 lasers are commonly used for engraving and cutting materials like wood, acrylic, and paper, while fiber lasers are more suitable for cutting metals.

Which type of laser is most used in industry?

Fiber lasers are the most commonly used lasers in the industry for cutting metals due to their high power and precision.

Is laser cutting business profitable?

Yes, a laser cutting business can be profitable if managed properly with a focus on providing high-quality services, competitive pricing, and effective marketing.

What are the 2 types of laser engraving?

The two types of laser engraving are vector engraving and raster engraving. Vector engraving creates sharp, clean lines, while raster engraving produces a softer, more textured effect.

Which is better 10W or 20W diode laser?

A 20W diode laser is generally better than a 10W diode laser because it has more power and can cut thicker materials more effectively.

What can a 1000W laser cut?

A 1000W laser can cut through thick materials like steel and aluminum, as well as thinner materials like wood, acrylic, and paper.

See Also :

- Best projectors for business

- Best screen printing machine for small business

- Best smartboard for business

- Best stump grinder for small business

- Best switches for small business